Due to the residue of WBN, HBN, pyrophyllite, graphite, magnesium, iron and other impurities in CBN micro powder. In addition, it and the binder powder contain adsorbed oxygen and water vapor, which is not good for sintering. Therefore, the purification of raw materials is one of the important steps to ensure the performance of polycrystalline synthesis. During the development, we used the following methods to purify CBN micro powder and binder materials: first, NaOH was used to treat CBN emblem powder at about 300 C to remove pyrophyllite and HBN. Then cook perchloric acid to remove the graphite.

Finally, the metal was removed by boiling with HCl on an electric heating plate and washing with distilled water until neutral.Co, Ni, and Al used as binders were treated by hydrogen reduction. Then, the CBN and the binder were mixed evenly according to a certain ratio and mixed into the graphite mold. The mixture was sent into a vacuum furnace with a pressure less than 1E2 and heated at 800 ~ 1000°C for 1h to remove the dirt, adsorbed oxygen and water vapor on the surface so that the surface of CBN grains was very clean.

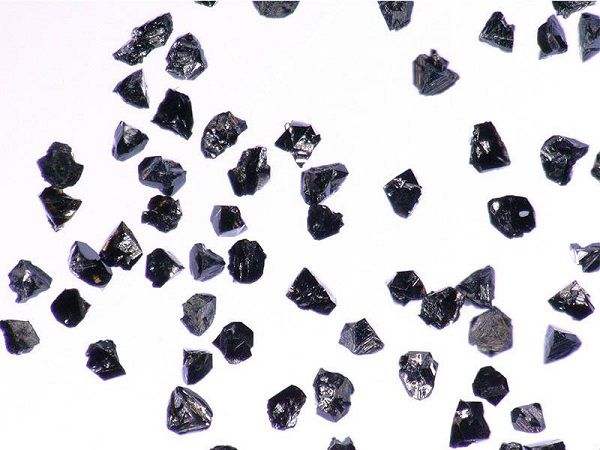

In addition to the choice of binders, the determination of CBN particle size and particle size ratio is also very important. The processing accuracy and surface quality requirements of root holder, the CBN particle size used in manufacturing cutting tools can be roughly divided into a coarse particle size of 20 ~ 30 nm. Medium particle size 3 ~ 10 microns. Fine particle size 2 microns. It is difficult to make high precision polycrystalline tools made of coarse grain, but its wear resistance, impact resistance is higher, fine-grain polycrystalline made of tools can meet the requirements of finishing and superfinishing.