BEIJING DEMINA PRECISION MACHINERY CO., LTD was founded in 2003. As the cutter regrinding advocate and pioneer of the industry, Deming, the company has accumulated rich experience in technology and service for product sales, dedicated to providing users with a more comprehensive solution. At present, our company developed countries all kinds of cutting tools and drill grinding equipment, can provide the most suitable products for different users, and provide a full range of technical advisory services; in Beijing the tool service center, Tianjin and surrounding areas provide manufacturing the overall carbide tool, the overall alloy bit and non standard cutting tools and grinding; also has more than 10 years of machine tool manufacturing and development experience of our company, development and production of BT150 series diamond tool grinding machine, universal tool grinding machine and BT560 type tool detection instrument, tool grinding machine CNC transformation and tool grinding application software. In 2016, we established a complete machine tool manufacturing and production base in Jing’an County, Jiangxi Province, and established Jiangxi Geqi Grinding Technology Co., Ltd. and Jiangxi Demina Precision Machinery Co., Ltd. And based on this, we trained the training of cutting talents.

Our factory has a total investment of 122.8 million yuan, covers an area of nearly 50 acres, of which the construction area is 23,466 square meters, with 1 office building, 2 warehouses, and 4,000 square meters of scientific research and living complex.

As an industry leader in the development and manufacture of tool grinding machines, Demina Manufacture Center has decades years of abundant experience in designing ability and professional manufacturing architecture. The center not only is a leading provider of PCD tool grinding machines and tool analyzers, but also provides the services such as CNC transformation of manual controlled tool grinding machines, the repairing of CNC tool grinding machines, the upgrading of controlling system, the updating of software and so on.

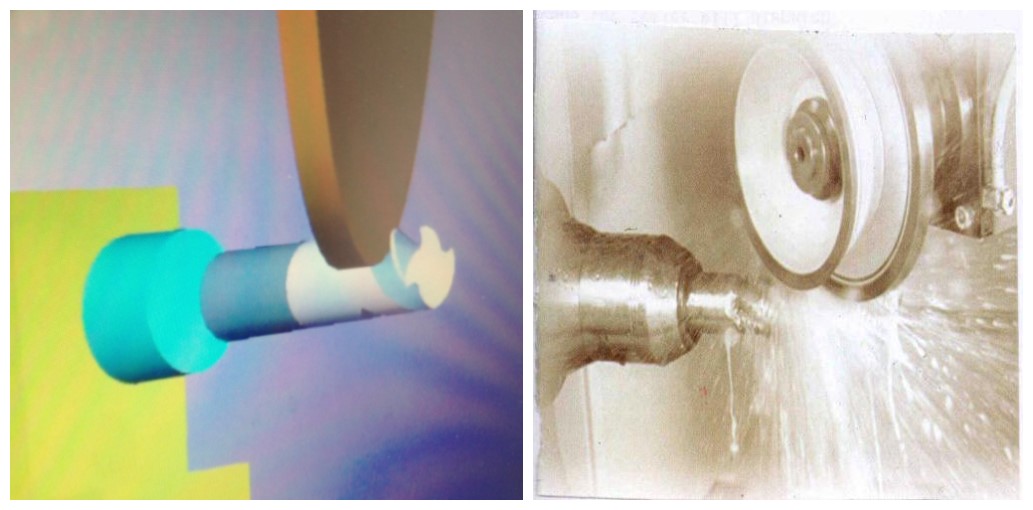

4-Axis CNC PCD Tool Grinder BT-150D

The machine is suitable for massive production of carbide insert, PCD and CBN insert. Once centering is finished, grinding will be done automatically. The even consumption of grinding wheel can be measured and compensated by the system, so production with long cycle time can be measured.

| Main Technical Parameters: | |

| The diameter of the Grinding wheel | 150mm |

| Direct Drive Spindle with Water Cooling | 3KW |

| RPM of Grinding Spindle | 0~3,000RPM |

| Changeable Clearance Angle | -5°~25° |

| Max Magnification of Optical Microcope | 4 times |

| Industrial PC and Display | 15 “ |

| Magnification of CCD Measuring System | 100times |

| Coolant Tank with Filter Paper | about70L |

| Electrical Supply | 12Kw |

| Voltage Requested | 380V/Three phrace/50Hz |

| Weight With Coolant Tank | 2000Kg |

BT-150J Superhard Tool Grinding Machine

BT-150J PCD Tool Grinder is reliable in performance and easy to be operated. It requests very little manual skill. The swinging of grinding wheel controlled by PLC is smooth and without reverse vibration. Without wheel handles it is easy to control the swing range, frequency, and swing position by pushing the button. The machine using ‘rapid feed’ and ‘precision feed’ to finish rapid feed/retraction (0.5mm/turn) and work feed(3mm/turn). This assures the production efficiency and feeds precision.

| Main Technical Parameters: | ||

| 1 | The diameter of the Grinding wheel | 150mm |

| 2 | Direct Drive Spindle with Water Cooling | 3KW |

| 3 | RPM of Grinding Spindle | 0~3000RPM |

| 4 | PLC Numerical Controlled Oscillation and Control on the Panel | |

| 5 | Max. Oscillation Range | 30mm |

| 6 | Max. Oscillation Frequency | 60times/minute |

| 7 | Quick approach withdraw and precisely feeding | 3mm/turn 0.5mm/turn |

| 8 | Feeding Resolution | 0.001mm |

| 9 | Magnification of CCD Measuring System | 100times |

| 10 | 15 Industrial Displayer | 15” |

| 11 | Electrical Supply | 12Kw |

| 12 | Voltage Requested | 380V/Three phrace/50Hz |

| 13 | Compressure of Air Braking on Rotation Axis | 6bar |

Drill Grinding Machine BT-40

Drill, tap, countersink cutter and step drill can be ground on BT-40 without extensive training. The vertical grinding wheel makes web thinning very easy. Six-jaw chuck with high accuracy guarantees the run-out a drill deserves.

| APE40 Technical Data: | |

| Sharpening diameter | 2~40mm |

| Point Angle | 40°~180° |

| Horizontal wheel spindle power | 0.76KW |

| Vertical wheel spindle power | 0.18KW |

| Wheel speed | 3380 RPM |

| Voltage | 24V |

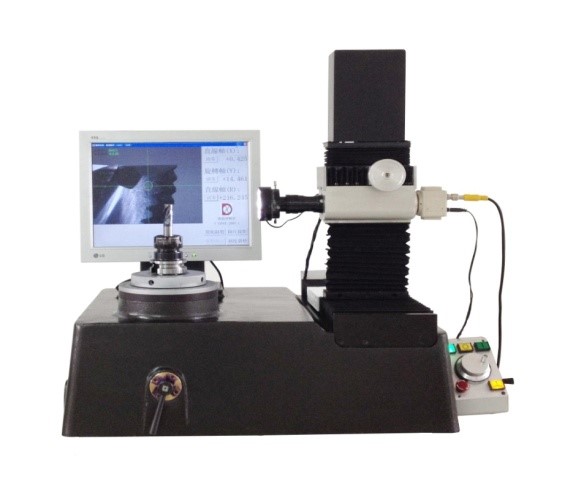

BT-560 Tool Analyzer

The analyzer is used for measuring the geometric elements(such as the diameter, radius, and the cutting edge angle) of drills and cutters. It makes use of the tool microscope and CCD camera to magnify the image and realize the real-time display, and the operating lever and electronic handwheel to set the measurement position quickly and precisely.

BT-150E 5-Axis CNC Tool Grinding Machine

BT-150E 5-Axis CNC Tool Grinder is equipped with special CNC system, with tool grinding application software based on Windows XP. It can grind drills, end mills, and ball nose of HSS and carbide. All the programs can be saved, copied, renamed and modified. Before starting grinding the tool, 2D simulation can be made and confirmed, so proper adjustment is possible.

| Technical Data: Work Head Frame | Hydraulic chuck BT 40 |

| Tool Diameter Range | 3-25mm |

| Maximum of Tool Length | 200mm |

| Maximum of Tool Diameter | 125mm |

| Wheel Center Hole | 20mm |

| Number of Wheel | 1-3 |

| Spindle Power | 5KW |

| Max.of Wheel Speed | 6000rpm |

| X-Axis Longitudinal Traverse | 360mm |

| Z-Axis Vertical Traverse | 180mm |

| Y-Axis Horizontal Traverse | 190mm |

| A-Axis Traverse | Endless |

| W-Axis Traverse | 0~200° |

| The accuracy of Linear Axis | 0.001mm |

| The accuracy of the Rotary Axis | 0.001° |

| Maximum of Linear Axis Feed Rate | 15m/min |

| Maximum of Rotary Axis | 60rpm |

| Controlling System | 5-axis control system of Germany Beckhoff |

| Measuring System | Data Encoder |

| Dimension | 2300x1800x2400(h)mm |

| Weight | 2000kg |

| Main Power | 380V |

| Voltage of Power | 10kw |

The production of BT150 series diamond tool grinding machine is suitable for massive production of carbide inserts, PCD and CBN inserts.

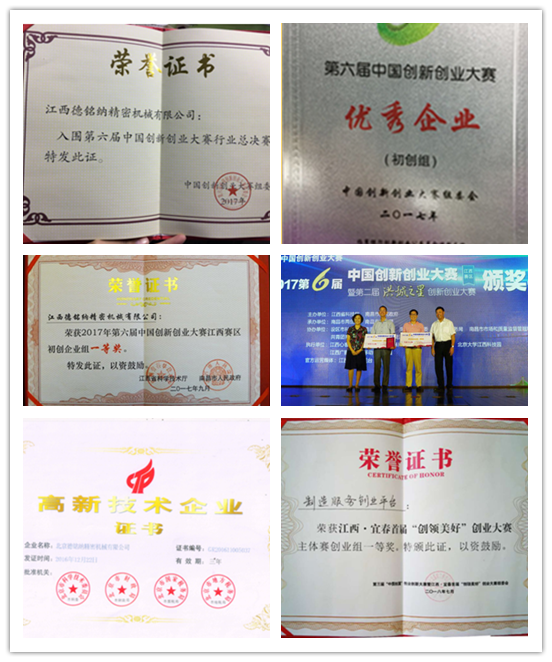

1. 150B 2-axis CNC diamond tool grinding machine won the Beijing New Technology and New Product Certificate

2. 150D 3-axis CNC diamond tool grinding machine won the Beijing New Technology and New Product Certificate

3. Beijing Demina Precision Machinery Co., Ltd. obtained the high-tech enterprise certificate

4. Beijing Demina Precision Machinery Co., Ltd. obtained Zhongguancun High-tech Enterprise Certificate

5. First Prize of the 6th China Innovation and Entrepreneurship Competition in Jiangxi Province

6. The Excellence Award in the Advanced Manufacturing Industry of the 6th China Innovation and Entrepreneurship Competition in 2017

7. In 2018, the first prize of the entrepreneurial group of the first “Creation of the Beautiful” Entrepreneurship Competition in Yichun, Jiangxi

8. Mr.Shu Zhiyong -the general manager of Demina Precision was selected as a leading entrepreneurial talent in the “Double Thousand Plan” of 2018 in Jiangxi Province.

Some Certificate pictures are as follows:

Our products are based on the Chinese market. And our customers include more than 20 provinces, municipalities and autonomous regions in China, and are exported to the United States, Mexico, Turkey and Japan, South Korea, Malaysia, Thailand, India, Singapore, Southeast Asia, and other countries.

Pre-sale:

Proactively provide the relevant information of our products to customers, give some suggestions to customers to purchase the machine that best suits their needs, and masters the machine ’s use and maintenance methods.

On-sale Service:

Respect customers and provide the best service.

Provide product technical consultation for users; confirm what they need and provide complete solutions for users.

After-sale:

We will follow the tracks of the whole process of product service and quality, pay full attention to customer complaints and suggestions, promptly feedback market information, make timely adjustments and immediately return products that cause quality problems to us, so that the company’s product quality and The service level is constantly improving and better serving the majority of users.