Beijing Deminna Precision machinery Co., LTD. As the pioneer and pioneer of tool heavy grinding industry, our company has accumulated rich technical and service experience in the process of product sales for many years, and we are dedicated to providing more comprehensive solutions for users. At present, our company ACTS as an agent for various kinds of cutting tools and bit and edge grinding equipment in developed countries and can provide the most suitable products for different users, and provide comprehensive technical consulting services. The company has set up a cutting tool service center in Beijing and a production center in Jingan, Jiangxi province.

From November 11 to November 14, Demina will participate in the 2020DME China (Dongguan) Machine Tool Exhibition. The exhibition will bring the new bt-150d type super hard (PCD&PCBN) tool grinder, BT-150N type super hard (PCD&PCBN) tool grinder, APE 40 drill grinder, and other products, and will be on sale to launch two hot style products: 1. Bt-150n type super hard (PCD&PCBN) tool grinder 2. BT-150Jmanual diamond tool grinder, then, welcomes people from all walks of life to visit and guide. Booth No. : 2A22

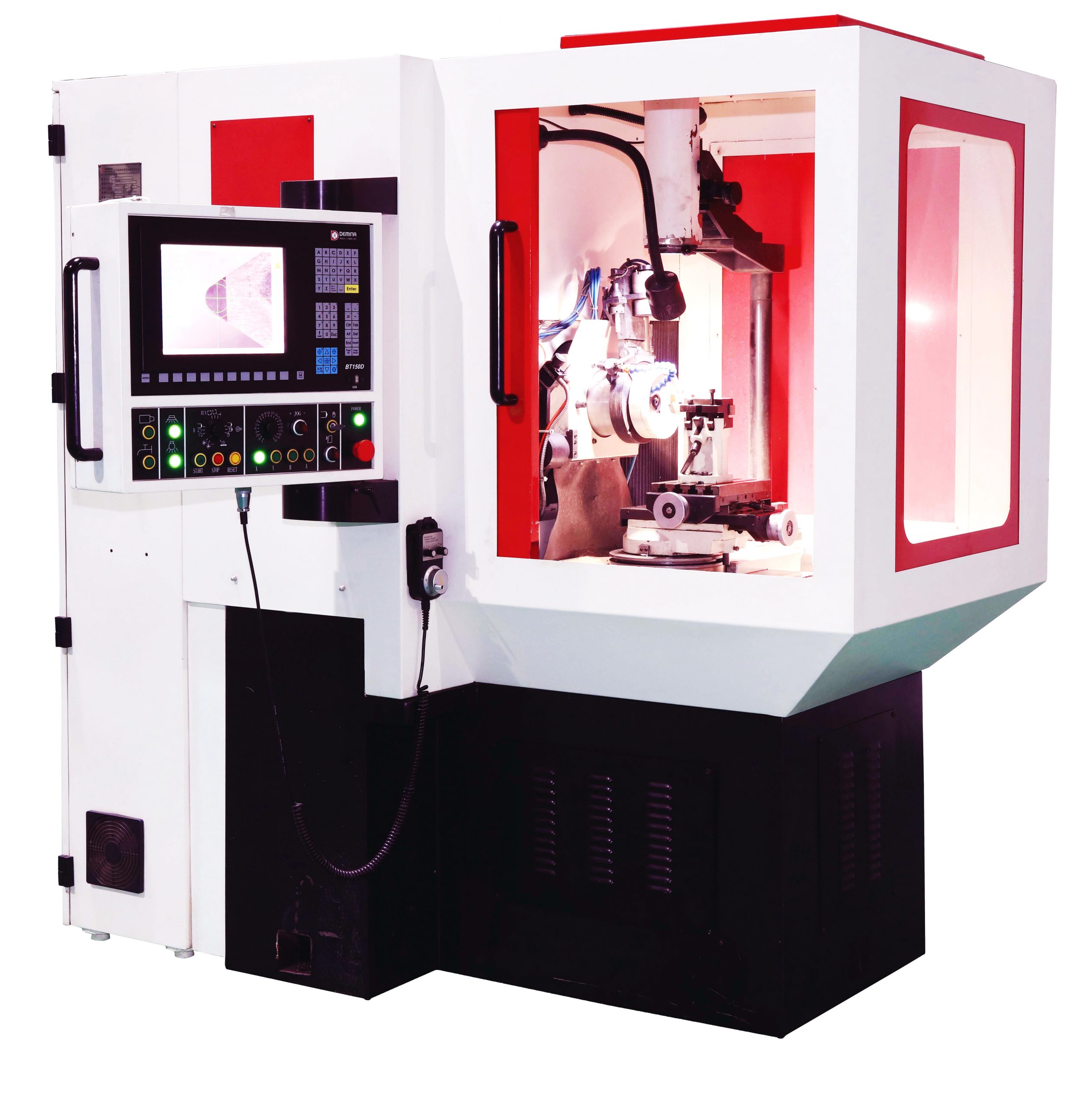

BT-150D is a four-axis CNC tool grinder, which is composed of four axes, such as the swing axis of the grinding wheel (X-axis), the tilt angle of the grinding wheel (B-axis), the rotation axis in the horizontal plane of the workpiece (C-axis) and the workpiece feed axis (Y-axis). The workpiece feed axis (Y-axis) is equipped with a grating ruler for closed-loop position feedback to ensure micron-level grinding accuracy. The machine is suitable for medium and large quantities of alloy blades, PCD blades, and CBN blades. As long as the center is completed, the system will automatically complete grinding under the action of the gravity of the hammer, realizing the ideal state of “constant pressure grinding, flexible feed”.Due to the high hardness of diamond material (PCD), the grinding wheel wears quickly. The system can detect and compensate the wear automatically, and maintain the dimensional accuracy of grinding for a long time.

BT-150N (PCD&PCBN) tool grinder the workpiece feed axis (Y-axis) is equipped with a grating ruler for closed-loop position feedback to ensure micron-level grinding accuracy. The machine is suitable for medium and large quantities of alloy blades, PCD blades, and CBN blades. As long as the center is completed, the system will automatically complete grinding under the action of the gravity of the hammer, realizing the ideal state of “constant pressure grinding, flexible feed”.The machine tool can be switched to manual mode through the control panel to suit the production model of small and medium batches and multiple varieties.