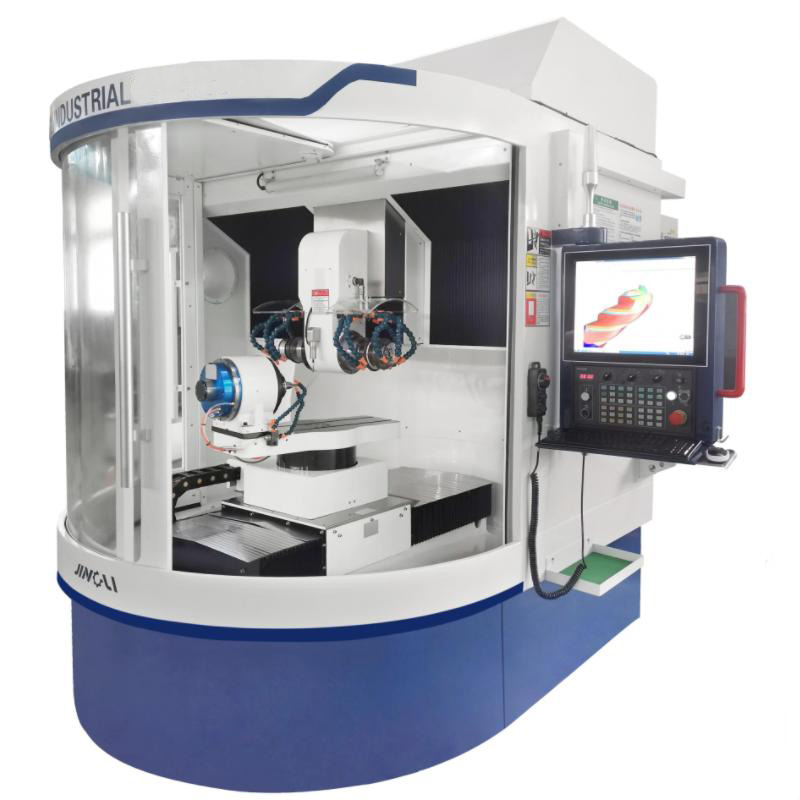

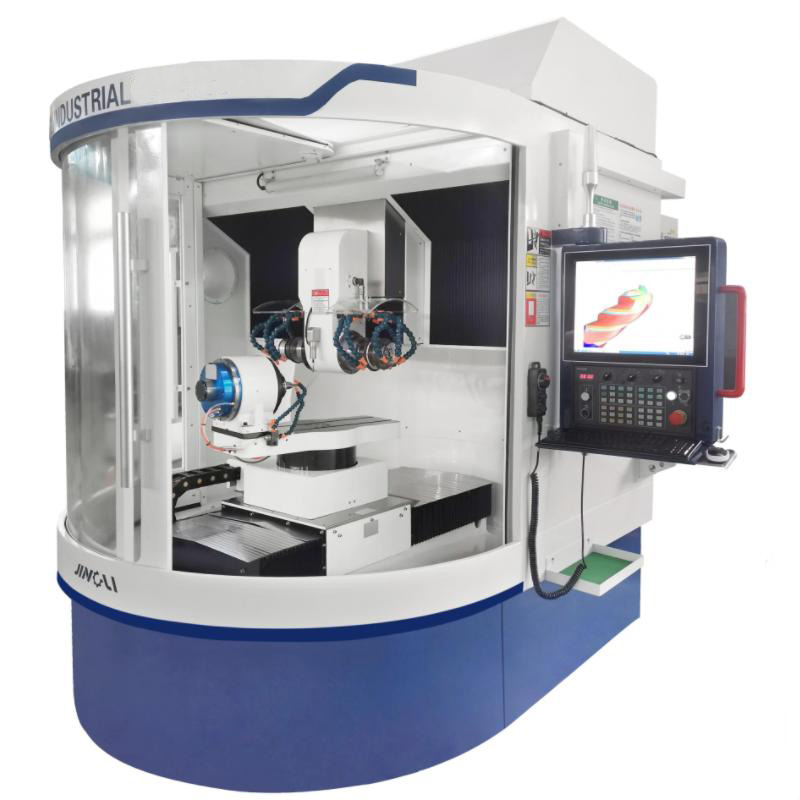

BT100 5-Axis CNC Tool Grinder is made by Beijing DEMINA, and equipped with special digital control system, based on Windows 7 tool grinding application software package. BT100 5-Axis CNC Tool Grinder is developed for full grinding tools. The machine tool is a five-axis and five-link machine tool, in which the X-axis、Y-axis and Z-axis is linear servo shafts and the A-axis and C-axis are rotating shafts. It is specialized in the production of standard milling cutters, drill bits, reamers, non-standard cutters, molding knives, and other cutting tools, with low efficiency, high precision CNC tool production equipment. In high-speed steel, cemented carbide milling cutter manufacturing field has extraordinary advantages.

1. In order to facilitate users to operate the machine, we also provide the instruction and parts manual, not including the quick-wear part;

2. One-year limited warranty;

3. Delivery time: 60 workdays after we received the deposit if any special requirement can be consulted;

4. Package: wooden case;

| Name | Model | Quantity |

| Grinding Wheel Bar | HSK50E-31.75 | 2 pieces |

| Spindle oil cooler | BL-10 | 1 set |

| Oil mist separator | LX-700 | 1 set |

| Dry transformer | 380V to 220V | 1 set |

| Automatic lubrication system | BT-A2 | 1 set |

| Grinding wheel gasket | 2 sets | |

| Electronically controlled air conditioning | FW-5 | 1 set |

| Tip (tail top) | 1 set | |

| Adjustable support | 1 set | |

| Tool cabinet | 1 case |